Air Pollution Control Plant

Air control Engineering Co., Ltd.

Bag Filter NANO Dust Collector

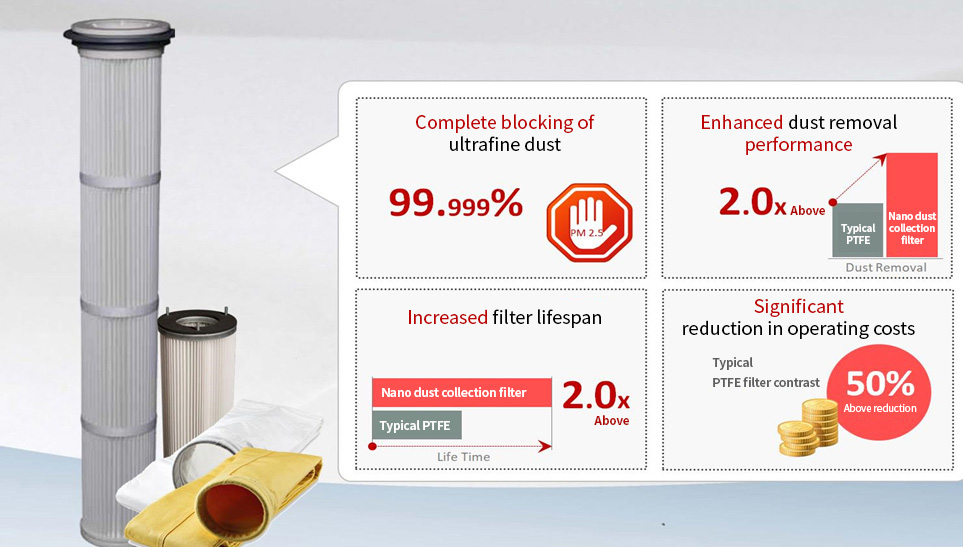

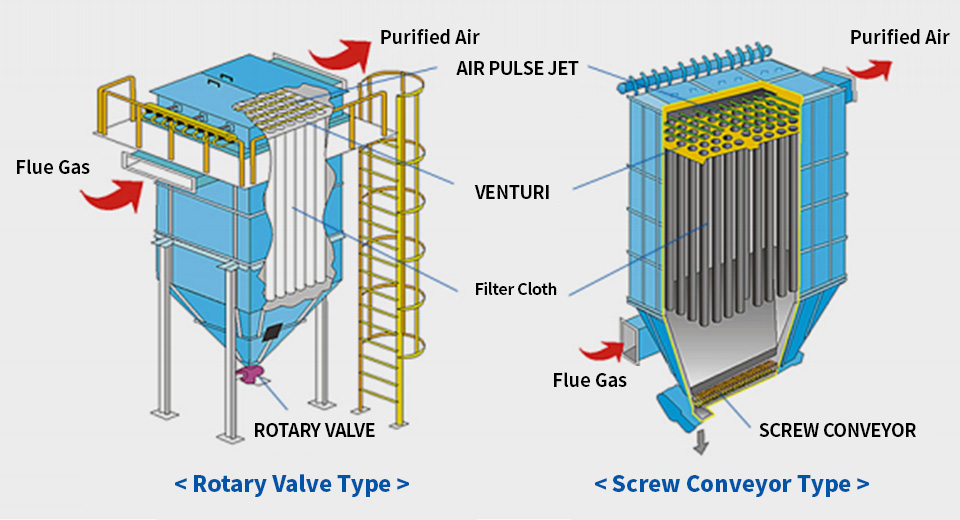

The filtration type dust collector uses bag filters to remove fine particles from flue gas through mechanisms of collision, blockage, diffusion, and electrostatics. Our bag filter collector is equipped with a NANO Bag Filter coated with fluoropolymer-based NANO fibers, capable of removing over 99% of particles as small as 0.3 µm.

The NANO bag filter has low pressure loss and, due to its surface filtration design, experiences less filter clogging compared to conventional bag filters. It also benefits from improved pulsing effects from air pulse jets, resulting in a longer lifespan. When used for the same applications as traditional bag filter dust collectors, the NANO Bag Filter dust collector can be designed with a smaller volume, reducing manufacturing costs and filter replacement expenses.

The NANO bag filter has low pressure loss and, due to its surface filtration design, experiences less filter clogging compared to conventional bag filters. It also benefits from improved pulsing effects from air pulse jets, resulting in a longer lifespan. When used for the same applications as traditional bag filter dust collectors, the NANO Bag Filter dust collector can be designed with a smaller volume, reducing manufacturing costs and filter replacement expenses.

Advantages

- Capable of handling various types of dust with high collection efficiency for fine particles.

- Gradual increase in pressure loss, allowing for the treatment of high-concentration dust.

- Provides long-term stable operation.

- Able to process dust of various capacities.

- Uses ultra-nano filter cloth, extending filter lifespan by 2 to 3 times compared to traditional bag filters.

- Retains the advantages of traditional bag collectors (e.g., diverse dust collection forms, long-term stability, high-concentration dust handling, and various capacity processing).

Application Case

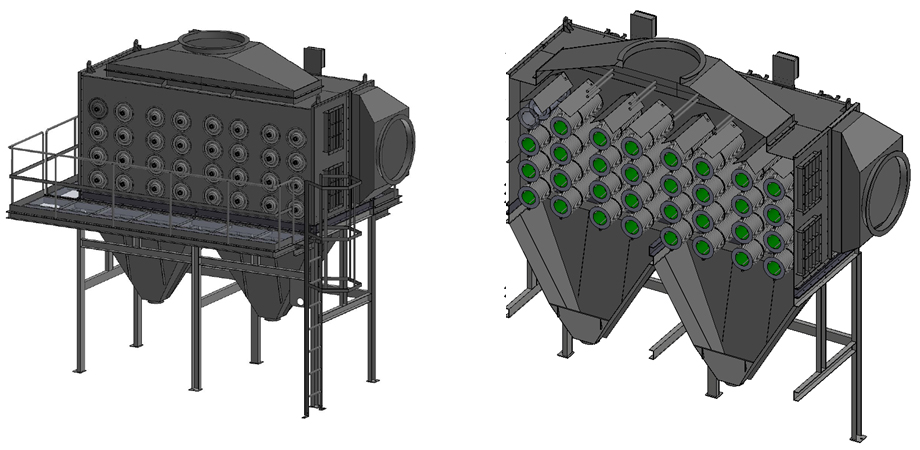

DOWNFLOW NANO DUST COLLECTOR

Downflow Dust Collector

In a downflow dust collector, contaminated gas enters from the top, and the airflow descends while being filtered. The downward airflow prevents dislodged dust from reattaching to the filter, resulting in lower operational load and longer filter lifespan.

Applications

- Can be used in sites producing and processing minerals, wood, cement, chemicals, pharmaceuticals, plastics, food, feed, grains, milling, and fertilizers.

- Due to the nature of fine dust, where conventional filtration media may clog too quickly or where standard PE bag filters are unsuitable, NANO Bag Filters can be applied.

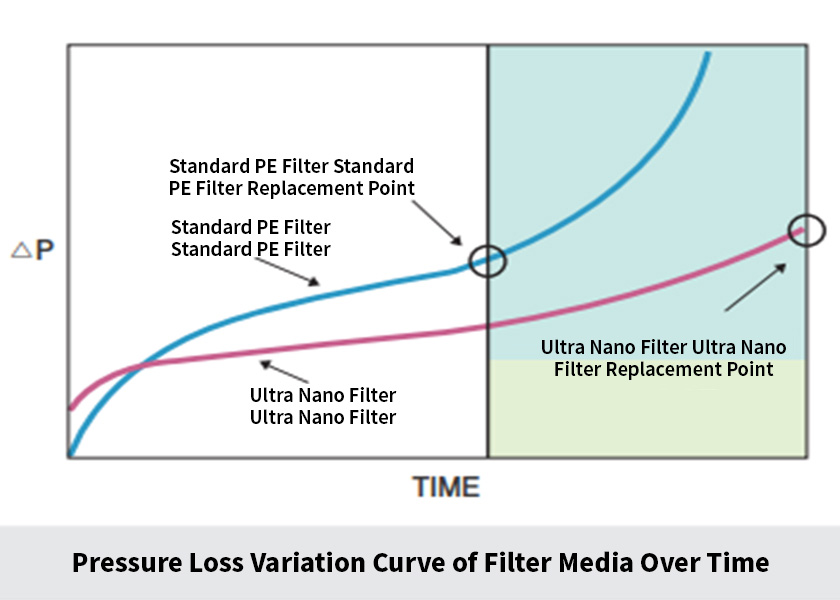

Change in Pressure Loss Over Time

NANO FILTER Usage

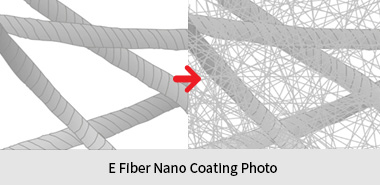

The filter is coated with nano material, allowing dust to be removed through surface filtration, making it easy for particles to be dislodged during air pulsing. The NANO filter can remove 99.1% of fine particles as small as 0.3 µm and experiences less clogging compared to standard filters, resulting in lower pressure loss.

NANO FILTER

| Category | NANO - FILTER | Standard PE – FILTER |

|---|---|---|

| Filter Material | POLYESTER or CELLULOSE | POLYESTER |

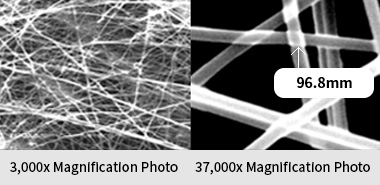

| Filter Coating / Filtration Method | NANO FIBER – SURFACE Filtration | FELT – DEPTH Filtration |

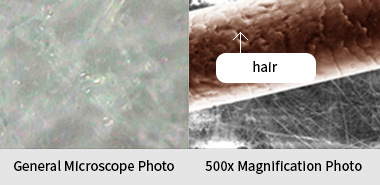

| Coating Description | Ultrafine-web FILTER coated with 0.15 micron NANO FIBER | No coating |

| Collection Efficiency | 99.9% for 0.5 µm | Over 98% for 5 µm |

| Operating Temperature | 80°C | 120°C |

| Abrasion Resistance | Excellent | Excellent |

| Chemical Resistance | Excellent | Excellent |

| Target Applications | Coating processes, pharmaceuticals, welding, laser fume, fine dust | General industrial processes generating dust |

| Applicable Dust Types | Silica fume, metallic fume, metal powders, oily welding fume, others | Metallic dust, grain powder, chemical dust, others |

| Scope of Application | Highly effective for very fine or non-fibrous dust and abrasive dust, with high filtration efficiency for particles below 1 µm. | Effective for industries with high contamination in chemical, food, and industrial processes, primarily effective for larger dust particles over 5 µm. |

COMPACT & Economical

- Due to these characteristics, the filter's lifespan can be extended by over 2 times compared to traditional filters, resulting in reduced replacement costs.

- With minimal restrictions on application, the cartridge-type filter structure increases the filtration area while reducing the overall size, minimizing installation space.

Nano Coating Filter

Advantages of NANO Filter