ACE Environmental Technology

Air control Engineering Co., Ltd.

Necessity of Wet Electrostatic Precipitators

Ammonia (NH3) gas that passes through a gas absorption tower reacts with acidic gases (such as SO3, HBr, HCl, HNO3, HF) to form ammonium, or creates fine droplets (0.1–1 µm) through the condensation of acidic gases (acid dew), leading to the phenomenon of white smoke. These fine droplets contain pollutant components and can be captured in samples during exhaust gas measurements, resulting in insufficient efficiency. Removing these submicron particles can be effectively achieved using electrostatic precipitators that utilize electrostatic forces for high-efficiency treatment.

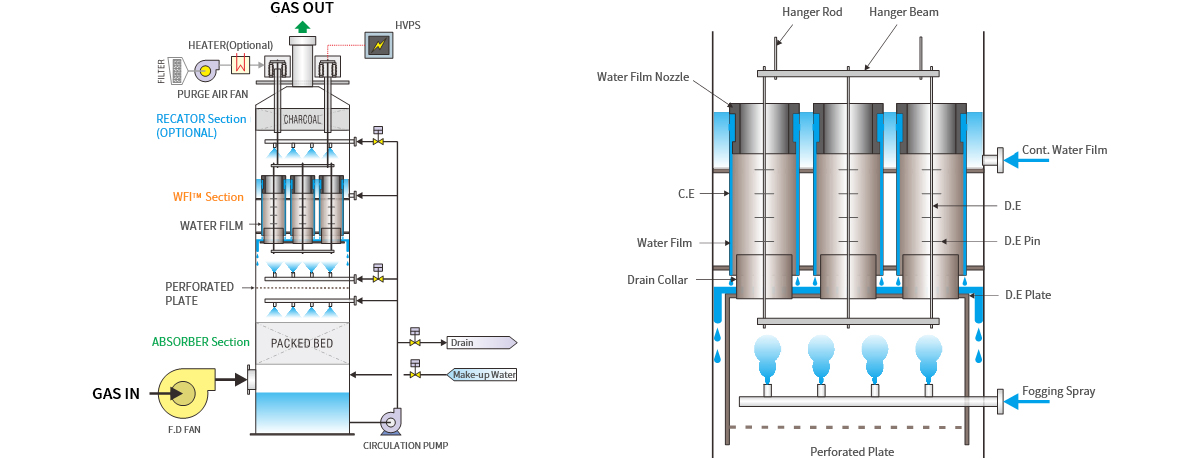

WF (Water film) Wet Electrostatic Precipitator Technology

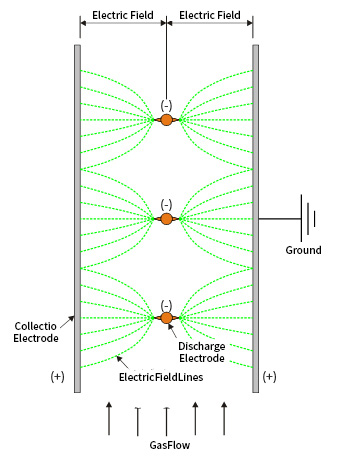

- The gas entering the electrostatic precipitation chamber is charged with negative ions at the discharge electrode (where high voltage is applied) through corona discharge. The incoming fine particles adsorb these negative ions, becoming electrically negatively charged.

- The charged particles move towards and adhere to the collection electrode (positive electrode, grounded) due to the Coulomb force between the electrodes and the charge on the particles.

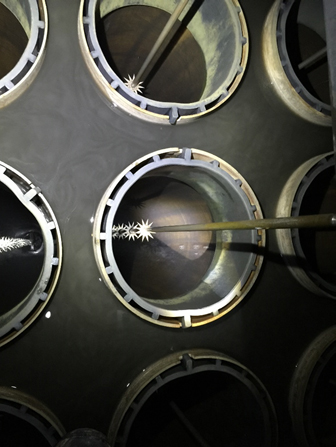

- Particles attached to the inner wall of the collection cylinder are carried away by the water film flowing along the wall and are then transferred to the lower circulation tank for removal.

Vertical Hybrid Water Film Wet Electrostatic Precipitator

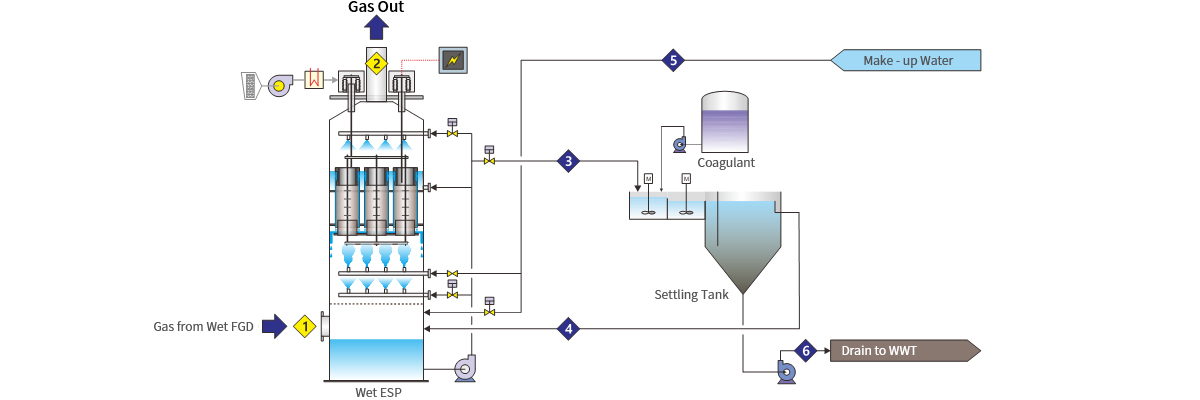

System Flow Diagram

Comparison of Dry and Wet Electrostatic Precipitators

| Item | Dry ESP | Wet ESP | Remarks |

|---|---|---|---|

| Purpose | Primary particle removal | Advanced particle removal | Wet type is for advanced treatment |

| Installation Location | Front | Rear | Wet type is installed at the final stage |

| Shape | Horizontal, plate | Vertical tube or horizontal/vertical plate | Wet type can be made in various shapes |

| Operating Humidity | 5~20 RH% | 100 RH% | Mainly applied close to 100% relative humidity |

| Temperature | 120~425°C | <100°C | Dry type operates above the sulfuric acid condensation temperature(>120℃) |

| High Concentration Dust Handling | Possible | Not possible | Wet type is less effective for high concentration dust |

| PM10 Removal | Optimal | Limited | Wet type is not effective for large dust removal |

| PM2.5 Removal | Average | Optimal | Wet type excels at removing submicron particles |

| Removal of Condensable Particles | Not possible | Optimal | Wet type is effective for removing condensable materials |

| H2SO4 Removal | Not possible | Optimal | Wet type is effective for removing sulfuric acid mist |

| Specific Collection Area (SCA) | 90~240 s/m | 15~60 s/m | |

| Treatment Velocity | 0.5~1.5 m/sec | 0.5~5.0 m/sec | |

| Pressure Loss | < 50 mmAq | < 50 mmAq | |

| Wastewater Generation | None | Yes | |

| Dust Resistivity Effect | High | None | Wet type is not affected by dust resistivity |

| Back Corona | Occurs | None | Wet type has no back corona phenomenon |

| Dust Re-entrainment | Occurs | None | Wet type has no dust re-entrainment |

| Material | Carbon steel | Plastic or corrosion-resistant steel | Wet type primarily uses corrosion-resistant non-metal materials |

| Cost | Relatively low | Relatively high |

Characteristics of Continuous Film Wet Electrostatic Precipitators (Water film wet electrstatic Precipitator)

- The collection electrodes can operate continuously for 24 hours due to the formation of a water film on the surface, preventing dust adhesion

- Fire prevention during operation by minimizing risks from arcs and sparks

- Collection plates can be made from non-conductive, corrosion-resistant materials suitable for strong acids (hydrochloric acid, sulfuric acid, nitric acid)

- Minimizes spark-over and short circuit phenomena for stable high efficiency

- No back corona phenomenon occurs even with high resistivity dust

- No re-entrainment of collected dust, making it suitable for handling moist fine particles

- Increased particle size due to contaminant condensation enhances the particle charge, resulting in improved collection efficiency

- Can be effectively combined with scrubbers and venturi scrubbers for an efficient treatment system

Advantages and disadvantages of Water Film Wet Electrostatic Precipitators

Advantages

- 1High collection efficiency.

- 2Capable of capturing very small particles with no minimum size limit for removal

- 3Low pressure loss (typically below 30 mmAq, with a maximum of 120 mmAq).

- 4Continuous operation with low maintenance costs

- 5Suitable for handling high-temperature and high-pressure gases

- 6Capable of processing large volumes of gas

- 7Low power consumption

Disadvantages

- 1Initial installation costs are high

- 2The electrical properties of the dust must be considered

- 3Safety precautions are necessary due to the use of high voltage electricity

Applications

- Removal of ultrafine particles (less than 0.1 µm).

- Removal of furan (heterocyclic compounds) and dioxins.

- Removal of heavy metal particles, mist, fume, and sticky particles.

- Removal of mist from hydrofluoric acid (HF) and sulfuric acid (H₂SO₄).

- Removal of ammonium nitrate (NH₄NO₃) and ammonium nitrite (NH₄NO₂).

- Removal of ultrafine particles (less than 0.1 µm).

- Removal of furan (heterocyclic compounds) and dioxins.

- Removal of heavy metal particles, mist, fume, and sticky particles.

- Removal of mist from hydrofluoric acid (HF) and sulfuric acid (H₂SO₄).

- Removal of ammonium nitrate (NH₄NO₃) and ammonium nitrite (NH₄NO₂).

Application Cases

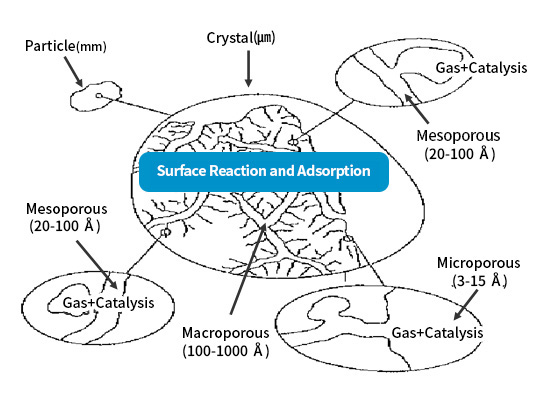

Chemical adsorption 이해

- 화학흡착제(chemical adsorbents)란 다공성의 물질에 제거하고자 하는 대상Gas와 효율적으로 반응하는 화학작용제를 첨착 혹은 혼합 성형하여 만든 제품을 말한다.

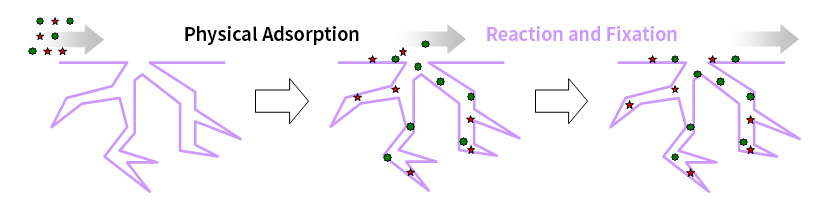

- 다공성 제품은 대상Gas의 물리적흡착(모세관 현상)을 용이하게 하여 화학작용제의 제거율을 극대화하는 역할을 하며, 화학작용제는 대상Gas와 반응을 하여 제거하는 물질로서 반응 후 다공성 기공내에 고착한다.

- 화학흡착제는 유기계 약재와 무기계 약재로 구분된다.

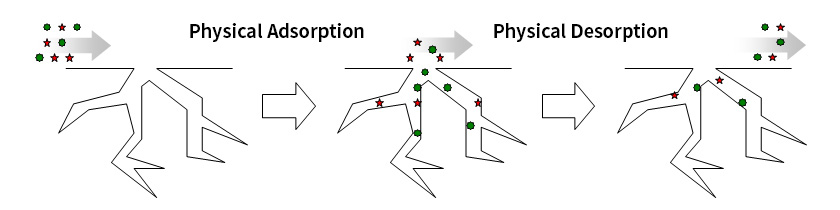

물리흡착 제거 원리

화학흡착 제거 원리

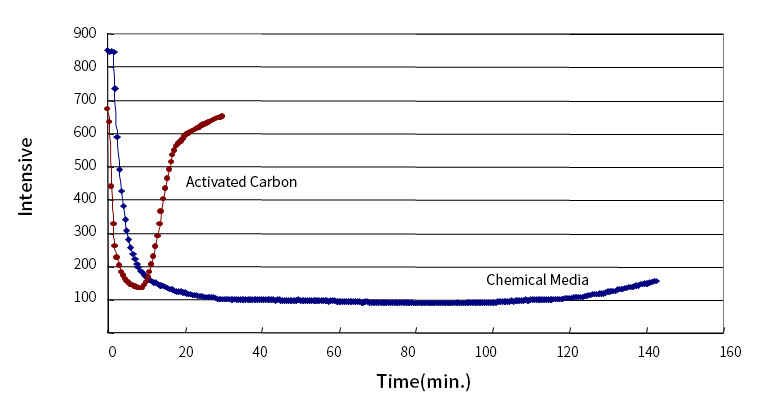

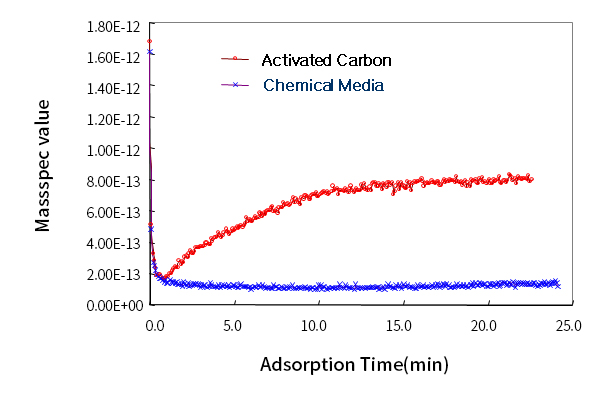

물리흡착 Vs 화학흡착 성능비교

흡착 성능 평가 [ TMA ; 트리메틸아민 ]

흡착 성능 평가 – Mercaptane

일반 활성탄에 10배의 흡착 성능

Chemical Media 종류

- MEDIA FOR SULFURIC GAS

- MEDIA FOR AMINE GAS

- MEDIA FOR ALDEHYDE GAS

- MEDIA FOR VOC GAS

- MEDIA FOR ACID GAS

- MEDIA FOR TOXIC GAS

- MEDIA FOR Influenza Virus & AI Virus

Table : Chemical Media List

| 구분 | Organic Media | Inorganic Media | Special | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Target Gas | CN | CS | CM | CX | CD | AM | ICA | AO | ST |

| NH3 | ● | ○ | |||||||

| SOx | ● | ● | |||||||

| NOx | ● | ● | |||||||

| O3 | ● | ||||||||

| Cl2 | ● | ● | |||||||

| HF | ● | ● | |||||||

| HCl | ● | ● | |||||||

| H2S | ● | ● | ● | ||||||

| MM | ● | ||||||||

| TMA | ● | ||||||||

| Ethylene | ● | ● | |||||||

| CO2 | ● | ||||||||

| CO | ● | ||||||||

| Aldehyde | ● | ||||||||

| PGMEA | ● | ||||||||

| PGME | ● | ||||||||

| Phosgene | ● | ||||||||

| Acetic Acid | ● | ○ | ○ | ||||||

| PFC | |||||||||

| VOC | ○ | ○ | ○ | ○ | ○ | ● | ○ | ||

| Virus | ● | ||||||||

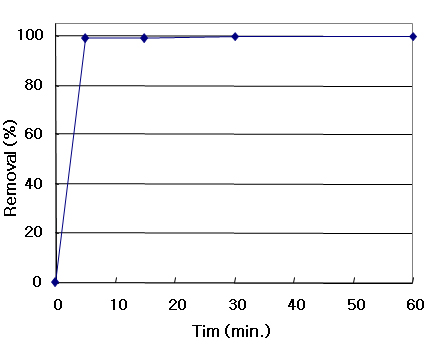

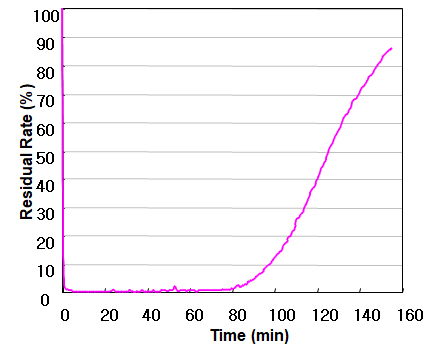

CAFILSORB-CN

NH3 Conc.: 50 ppm, S.V= 1,200 min-1,

RH = 50%, Mass Analyzer

Product information

| Composition | Chemical impregnated carbon | |

|---|---|---|

| Particle shape | Extrudated | Crushed |

| Target contaminants | NH3, TMA, Amine, Amide | |

| Use | Filling in case or coating on supported material | |

| Application | Living room, Toilet, Office | |

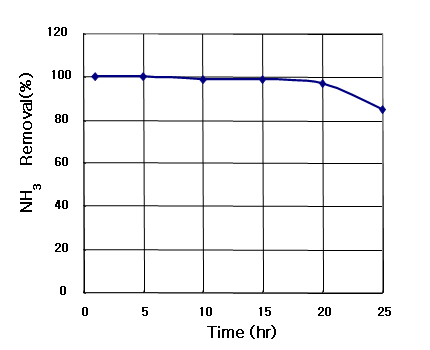

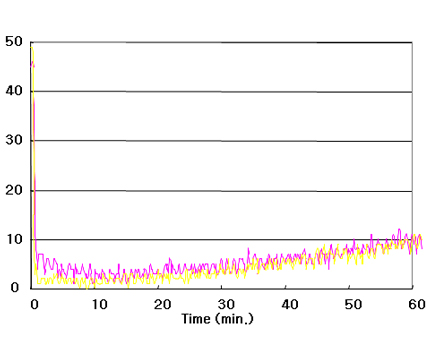

CAFILSORB-AM

SO2 Conc.: 200 ppm, S.V= 3,6000 hr-1,

RH = 50%, Gas Sensor

Product information

| Composition | Chemical impregnated metal oxide | |

|---|---|---|

| Particle shape | Sphere | Extrudated |

| Target contaminants | Sulfur compounds, NOx, Ethylene | |

| Use | Filling in casel | |

CAFILSORB-CS

Acetic acid Conc.: 1㎕, Chamber Test

RH = 50%, Chemical test kit

Product information

| Composition | Chemical impregnated carbon | |

|---|---|---|

| Particle shape | Extrudated | Crushed |

| Target contaminants | SOx & NOx, H2S, Acid compounds | |

| Use | Filling in case or coating on supported material | |

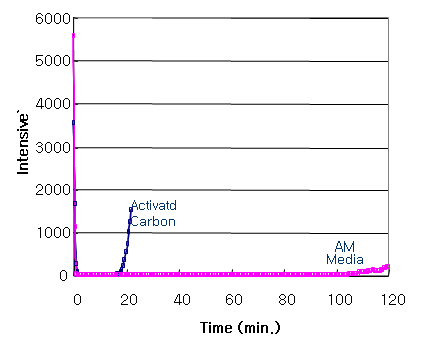

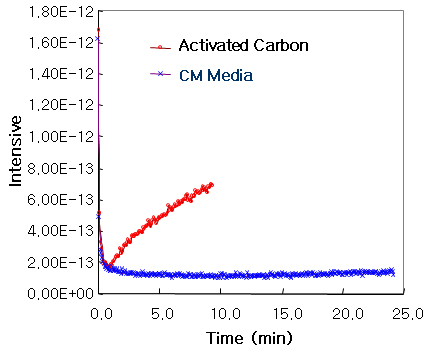

CAFILSORB-CM

Methyl Mercaptan Conc.: 500 ppm,

Flow Rate 100cc/min, Mass Analyzer

Product information

| Composition | Chemical impregnated carbon | |

|---|---|---|

| Particle shape | Extrudated | Crushed |

| Target contaminants | Sulfur compounds, Organic acids, Phosgene etc. | |

| Use | Filling in case or coating on supported material | |

| Application | Refrigerator, Kitchen | |

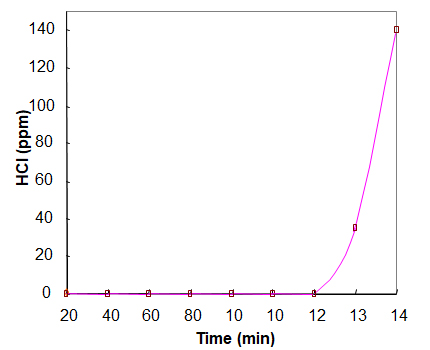

CAFILSORB-ICA

HCl Conc.: 10,000 ppm,

Flow Rate 650cc/min, Mass Analyzer

Product information

| Composition | Metal oxide mixture |

|---|---|

| Particle shape | Extrudated(Crushed) |

| Target contaminants | Chlorine, Hydrochloric acid, Carbon dioxide |

| Use | Swimming pools, PVC molding utility |

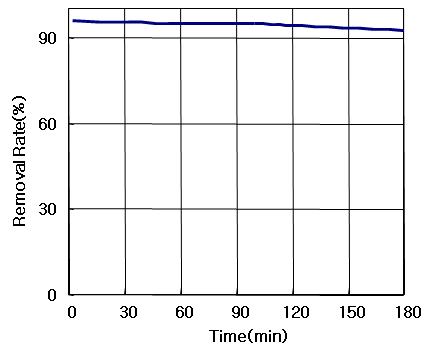

CAFILSORB-CX

Ozone Conc.: 2,000 ppm,

Flow Rate 2,000cc/min, Mass Analyzer

Product information

| Composition | Chemical impregnated carbon | |

|---|---|---|

| Particle shape | Extrudated | Crushed |

| Target contaminants | VOCs, Ozone, Hydrocarbons | |

| Use | Filling in case or coating on supported material | |

| Application | Kitchen, Electric Heater | |

CAFILSORB-CD

Acetaldehyde Conc.: 330 ppm,

Flow Rate 340cc/min, Mass Analyzer

Product information

| Composition | Chemical impregnated carbon | |

|---|---|---|

| Particle shape | Extrudated | Crushed |

| Target contaminants | Acetaldehyde, Formaldehyde, Acetic acid | |

| Use | Filling in case or coating on supported material | |

CAFILSORB-AO

Carbon Mono-oxide Conc.: 50 ppm,

Flow Rate 1,000cc/min, Mass spec.

Product information

| Composition | Chemical impregnated metal oxide |

|---|---|

| Particle shape | Sphere |

| Target contaminants | Carbon mono-oxide, Aldehydes |

| Use | Filling in case |

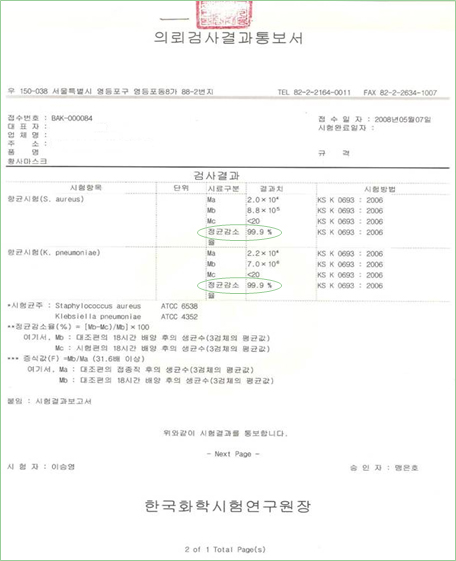

CAFILSORB-ST

KTR의 “살균력 평가”

- 1Staphylococcus Aureus (황색포도상구균)

- 2Klebsiella Pheumoniae (폐렴막대균) => 평가 결과 : 살균력 99.9%

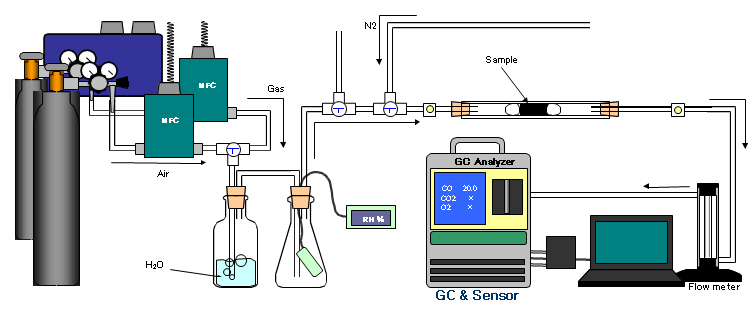

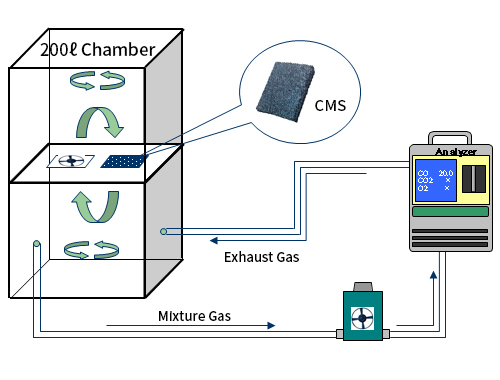

Ref. Analyzer for Deodorant

Test Utility Ⅰ

Test Utility Ⅱ

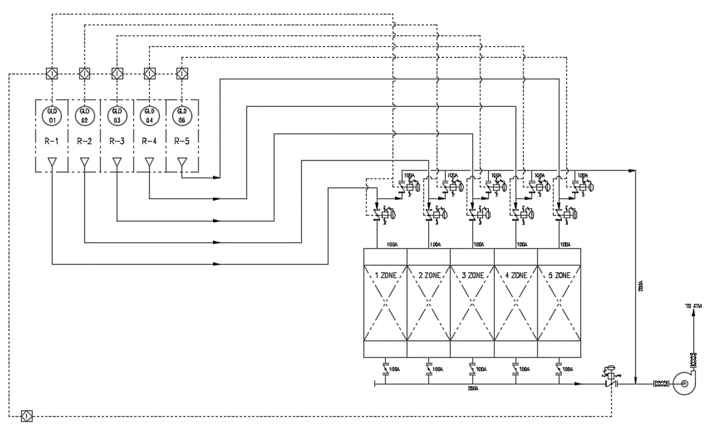

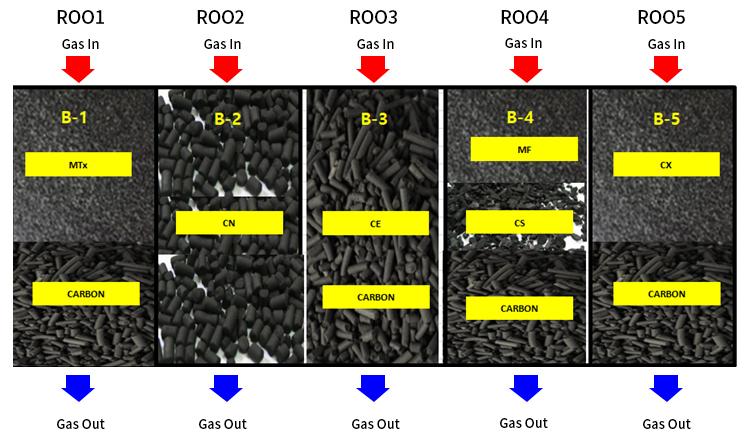

독성가스기보관소별 Cemical adsorption 반응식

| ROOM NO | 구 분 | GAS NAME (영문) |

CHEMICAL ADSORPTION | CHEMICALL ADSORBENTS | 반응식 |

|---|---|---|---|---|---|

| R-1 | 독성창고 1 | ASH2 | B-1 | 4AsH2 + 11CuO → 2Cu2As + As2O5 + 7Cu + 6H2O | |

| SiH4 | MTx | SiH4 + 2MOH →àM2Si + 2H2O + H2 | |||

| Si2H6 | CARBON | Si2H6 + 4MOH →à2M2Si + 4H2O + H2 | |||

| B2H6 | B2H6 + 3CuO → B2O3 + 3Cu+3H2 | ||||

| PH3 | PH3 + 3CuO → Cu3P + P + 3H2O | ||||

| R-2 | 독성창고 2 | ASH2 | B-2 | ||

| NH3 | CN | NH3 + MeSOx →à(NH3)nSOx | |||

| R-3 | 독성창고 3 | C2H4O | B-3 | C2H4O --> 흡착제거 | |

| CO | CE | CO + O2 → CO2 | |||

| HC | CARBON | HC ---> 흡착제거 | |||

| R-4 | 독성창고 4 | HCI | B-4 | MF | 3HCl + MO(OH) →àMCl3 + 2H2O |

| NF3 | CARBON | NF3 : NF3 + A/C → 흡착제거 | |||

| CI2 | CS | Cl2 + 2MOH → 2MCl + H2O + 1/2O2 Cl2 + M(OH)2 → MCl2 + H2O + 1/2O2 |

|||

| R-5 | 독성창고 5 | NO | B-5 | CARBON | AC + NO → CN*, CNO*, CNO3* |

| so2 | CX | MeOH + SO2 → MeSOx + H2O |

P & ID

Chemical Adsorption Tower

ADSORPTION TOWER DESIGN

흡착탑 설계기준

- 공탑 속도 : 0.35~0.5m/sec

- 체류시간 : 1 sec 이상

- Depth (흡착제 충진 두께) : 500mm

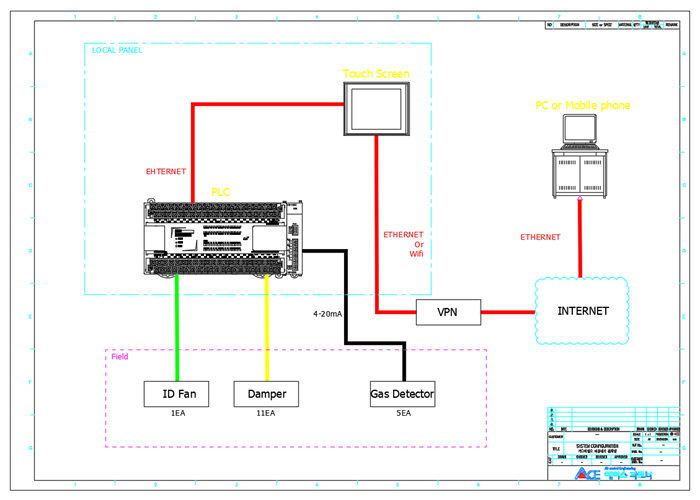

Control

Gas Chemical Adsorption Tower Operation Manual

| 상황 | 운전방법 1 | 운전방법 2 | 비고 |

|---|---|---|---|

| 평상시(GAS 유출없음) | 방지시설 및 배기팬 정지 | ROOM의 음압을 유지하기위해 배기팬만 운전 방지시설은 미운전 ( VALVE OFF) | 상황에 따라 운전방법 결정 |

| ROOM내부에 GAS 유출 발생시 | GAS DETECTOR SETTING 농도에 따라 감지 -> FAN/방지시설 운전 / ALARM 송출 -> 감지농도 이하로 떨어지면 FAN/ALARM 정지 | -> 유출된 ROOM에 설치된 GAS DETECTOR SETTING 농도에 따라 감지 -> 해당 방지시설 VALVE OPEN / ALARM 송출 -> 감지농도 이하로 떨어지면 해당방지시설 VALVE OFF & ALARM 정지 | |

| Event 발생 후 조치 | 유출 ROOM 및 방지시설 점검 -> 필요에 따라 Chemical Media 교체 진행 | 유출 ROOM 및 방지시설 점검 -> 필요에 따라 Chemical Media 교체 진행 |