ACE Environmental Technology

Air control Engineering Co., Ltd.

VOCs & Odor Treatment Technologies

Types of Volatile Organic Compounds

| No | Product & Material name | Molecular formula | CAS No. |

|---|---|---|---|

| 1 | Acetaldehyde | C2H4O[CH3CH0] | 75-07-0 |

| 2 | Acetylene | C2H2 | 74-86-2 |

| 3 | Acetylene Dichloride | C2H2C12 | 540-59-0 |

| 4 | Acrolein | C3H4O | 107-02-8 |

| 5 | Acrylonitrile | C3H3N | 107-13-1 |

| 6 | Benzene | C6H6 | 71-43-2 |

| 7 | 1,3-Butadiene | C4H6 | 106-99-0 |

| 8 | Butane | C4H10 | 106-97-8 |

| 9 | 1-Butene, 2-Butene |

C4H8[CH3CH2CHCH2)], C4H8[CH3(CH)2CH3] |

106-98-9, 107-01-7 |

| 10 | Carbon Tetrachloride | CCl4 | 56-23-5 |

| 11 | Chloroform | CHCl3 | 67-66-3 |

| 12 | Cyclohexane | C6H12 | 110-82-7 |

| 13 | 1,2-Dichloroethane | C2H4Cl2[Cl(CH2)2Cl] | 107-06-2 |

| 14 | Diethylamine | C4H11N[(C2H5)2NH] | 109-89-7 |

| 15 | Dimethylamine | C2H7N | 124-40-3 |

| 16 | Ethylene | C2H4 | 74-85-1 |

| 17 | Formaldehyde | CH2O[HCHO} | 50-00-0 |

| 18 | n-Hexane | C6H14 | 110-54-3 |

| 19 | Isopropyl Alcohol | C3H8O[(CH3)CHOHCH3] | 67-63-0 |

| 20 | Methanol | CH4O[CH3OH] | 67-56-1 |

| 21 | Methyl Ethyl Ketone | C4H8O[CH3COCH2CH3] | 78-93-3 |

| 22 | Methylene Chloride | CH2Cl2 | 75-09-2 |

| 23 | Methyl Tertiary Butyl Ether | C5H12O[CH3OC(CH3)2CH3] | 1634-4-4 |

| 24 | Propylene | C3H6 | 115-07-1 |

| 25 | Propylene Oxide | C3H6O | 75-56-9 |

| 26 | 1,1,1-Trichloroethane | C2H3Cl3 | 71-55-6 |

| 27 | Trichloroethylene | C2HCl3 | 79-01-6 |

| 28 | Gasoline | - | 86290-81-5 |

| 29 | Naphtha | - | 8030-30-6 |

| 30 | Crude Oil | - | 8002-5-9 |

| 31 | Acetic Acid | C2H4O2 | 64-19-7 |

| 32 | Ethylbenzene | C8H10 | 100-41-4 |

| 33 | Nitrobenzene | C6H5NO2 | 98-95-3 |

| 34 | Toluene | C7H8 | 108-88-3 |

| 35 | Tetrachloroethylene | C2Cl4 | 127-18-4 |

| 36 | Xylene | C8H10 | 1330-20-7 (95-47-6, 108-38-3, 106-42-3) |

| 37 | Styrene | C8H8 | 100-42-5 |

Optimal VOCs Treatment Systems by Emission Concentration

| Inlet THC Concentration (ppm) |

Treatment Method | Detailed Description | ||

|---|---|---|---|---|

| ~ 35 ~ | Adsorption Exchange | Replace with a new adsorbent once it becomes saturated after adsorption. | ||

| Adsorption Regeneration | Regenerate the adsorbent using heat or pressure after it becomes saturated | |||

| ~ 350 ~ | Concentrator | + | Direct Incineration | Directly incinerate the components that have been concentrated and desorbed from the concentrator |

| Regenerative Thermal Oxidizer (RTO) | Incinerate the components that have been concentrated and desorbed from the concentrator with a regenerative thermal oxidizer. | |||

| Regenerative Catalytic Oxidizer (RCO) | Incinerate the components that have been concentrated and desorbed from the concentrator with a Regenerative Catalytic Oxidizer | |||

| ~ 3,500 ~ | Direct Incineration (TO) | Directly incinerate the incoming components. | ||

| Regenerative Thermal Oxidizer (RTO) | Incinerate the incoming components with a regenerative thermal oxidizer | |||

| Regenerative Catalytic Oxidizer (RCO) | Incinerate the incoming components with a Regenerative catalytic oxidizer | |||

| ~ 35,000 | Dilution Incineration | Dilute the incoming components to a non-explosive concentration and then incinerate them directly | ||

| Concentration Recovery | Adsorb and desorb (concentrate) the incoming components, then cool and condense them for recovery | |||

| > 35,000 | Condensation Recovery | Cool and condense the incoming components for recovery. | ||

Characteristics of VOCs Treatment Technologies

| Control Technology | Capital Cost | Operating Cost | Actual Field Usage | Process Flexibility | High-Volume Capacity | Applicability to Low-Concentration Contaminants |

|---|---|---|---|---|---|---|

| Thermal Incineration | High | High | O | O | O | O |

| Adsorption | High | Moderate | O | O | O | O |

| Absorption | Low | Moderate | O | X | O | O |

| Condensation | High | Moderate | O | X | X | O |

| Biological Filtration | Moderate | Low | △ | O | X | O |

| Catalytic Oxidation | Moderate | Moderate | X | O | X | X |

| Photocatalytic Oxidation | Moderate | Low | X | O | X | X |

Characteristics and Advantages/Disadvantages of VOCs Treatment Facilities

| Technology | Characteristics and Advantages | Disadvantages | Applicable Process |

|---|---|---|---|

| Direct Incineration (TO) |

|

|

|

| Catalytic Oxidizer (CO) |

|

|

|

| Regenerative Thermal Oxidizer (RTO) |

|

|

|

| Regenerative Catalytic Oxidizer (RCO) |

|

|

|

| Adsorption (Concentration) (ROTOR) |

|

|

|

VOCs Treatment Technology

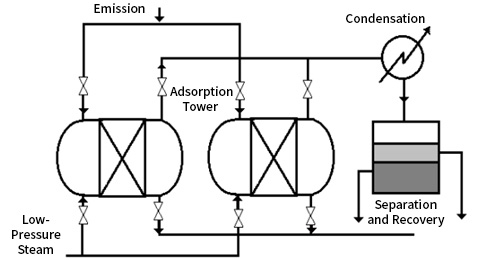

Adsorption Regeneration Method

Adsorption towers are typically cylindrical vessels filled with granular adsorbents, such as activated carbon, and screens are installed to retain the adsorbent. There are two configurations for adsorption towers: vertical and horizontal. Horizontal towers are mainly used for handling large volumes of gas. For continuous gas treatment, two adsorption towers are connected in parallel to alternate between adsorption and regeneration. The face velocity is usually designed between 9-30 m/min, and the residence time ranges from 0.6-6 seconds.

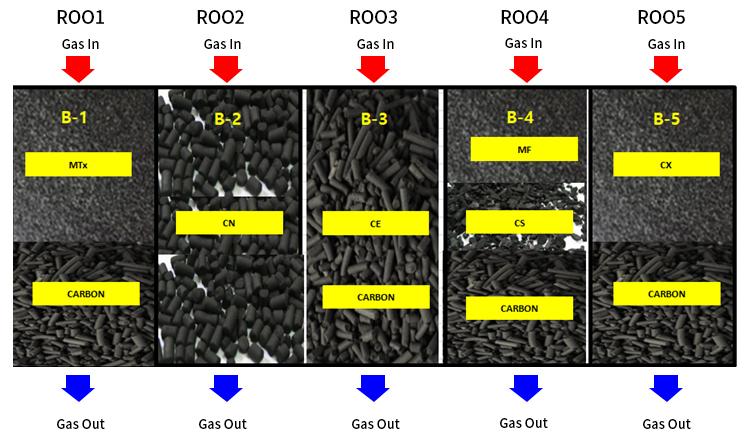

CHEMACAL ADSORPTION

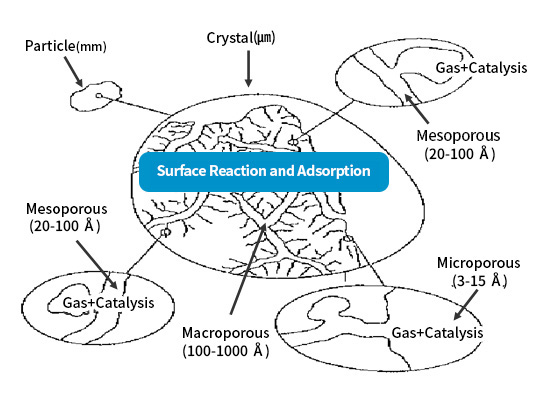

- Chemical adsorbents are products created by attaching or mixing chemical agents with porous materials that efficiently react with the target gas to be removed.

- The porous structure facilitates the physical adsorption of the target gas (through capillary action), enhancing the effectiveness of the chemical agents in removing the gas. After reacting with the target gas, the chemical agents become fixed within the pores of the porous material.

- Chemical adsorbents are classified into organic and inorganic materials.

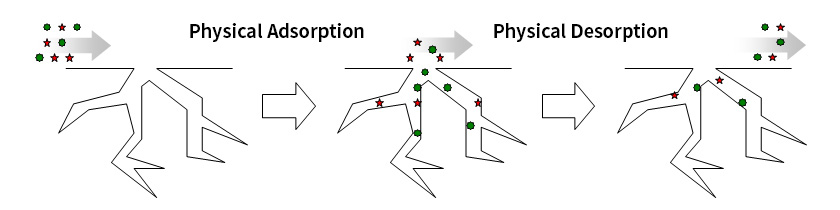

Principle of physical adsorption removal

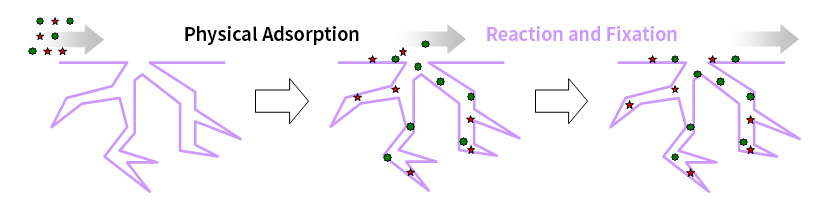

Principle of Chemical Adsorption Removal

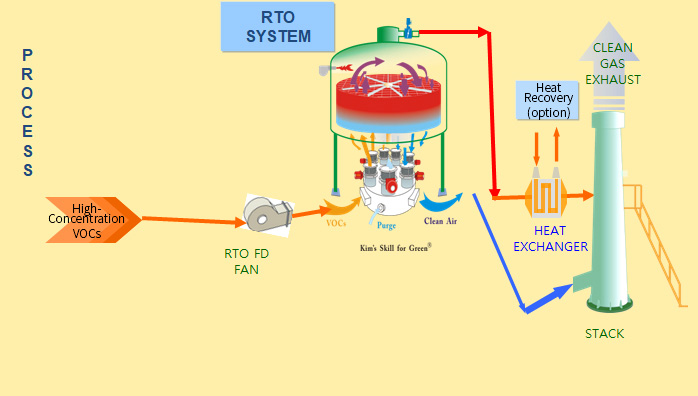

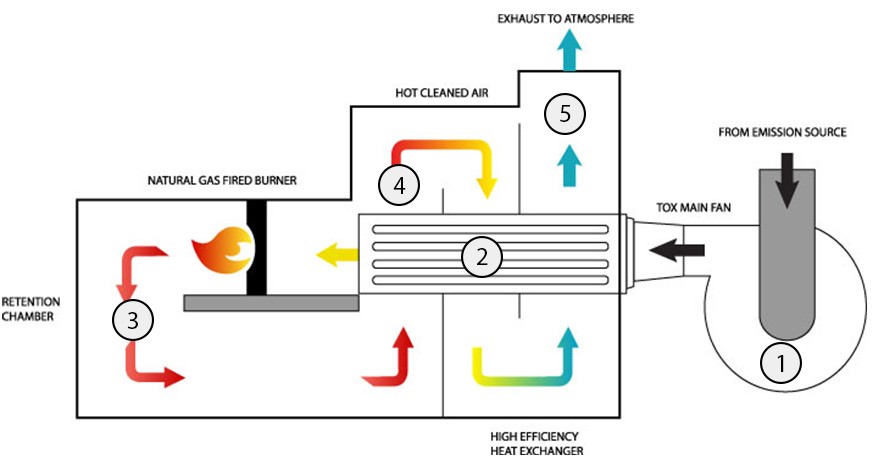

Regenerative Thermal Oxidizer RTO

An RTO (Regenerative Thermal Oxidizer) is a device that combusts volatile organic compounds (VOCs) at high temperatures of 800°C, achieving over 99% removal efficiency. It utilizes ceramic thermal storage media to recover more than 95% of the heat generated during the combustion of VOCs, minimizing the consumption of supplemental fuels.

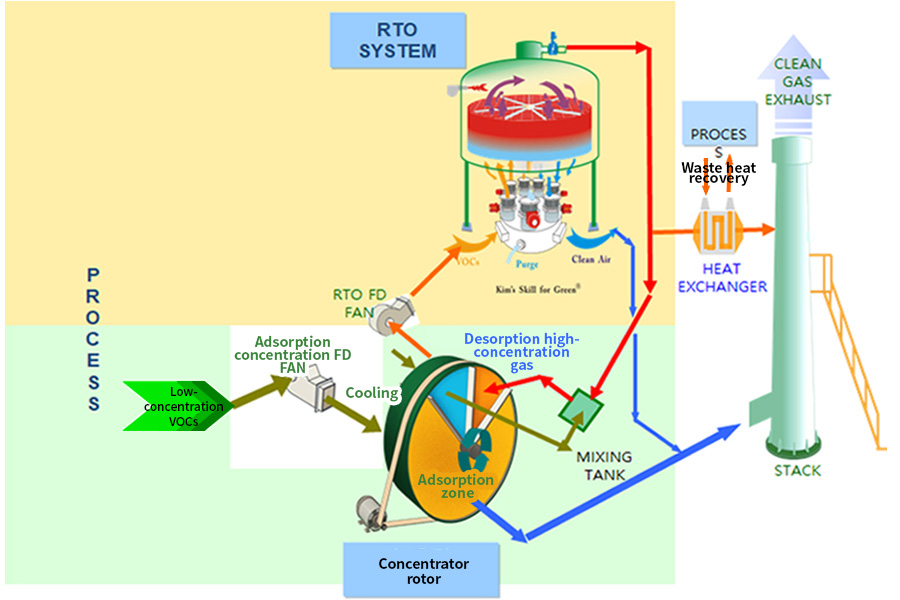

Concentrator + Regenerative Thermal Oxidizer RTO

- Low-concentration, high-flow VOC-containing air is concentrated into high-concentration, low-flow air using a concentrator, and then oxidatively decomposed in the combustion unit

- Concentration treatment enables the combustion unit to be compact and integrated, allowing for reduced costs and a more compact design

- Concentration treatment reduces fuel consumption in the combustion unit, utilizing the combustion exhaust as a heat source for regeneration

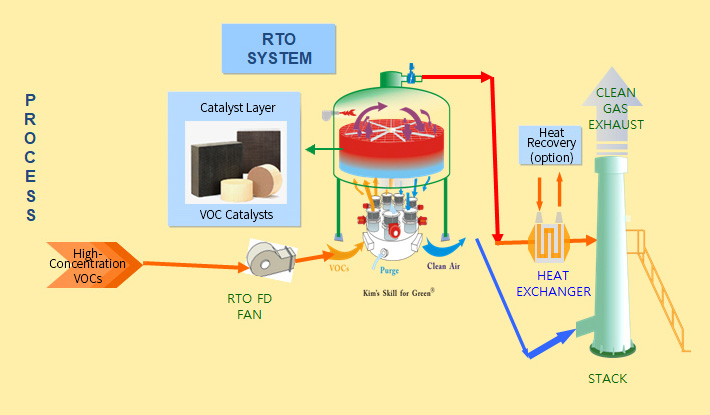

Catalystic Thermal Oxidizer

- Applicable for the treatment of low-concentration exhaust gases

- Applicable catalysts & operating temperature: Low-temperature oxidation catalyst, ozone oxidation: 180–220℃; medium and high-temperature oxidation catalysts: 300–450℃

- Applications: Plating, printing, flexible packaging, petrochemical processes

- Apply appropriate catalysts and oxidation methods based on generated pollutants.

- Advantages : Reduced energy costs due to low-temperature operation, lower fire risk

- Disadvantages : Requires catalyst selection suitable for operating conditions, not applicable in the presence of organic silicon and toxic substances in the gas

Catalytic combustion device RCO

A catalyst is a substance that lowers the activation energy required for a chemical reaction, promoting the reaction rate at relatively low temperatures. Catalytic combustion uses oxidation catalysts such as platinum (Pt), rhodium (Rh), and palladium (Pd) to initiate oxidation reactions at 200–400℃ using oxygen from the air.

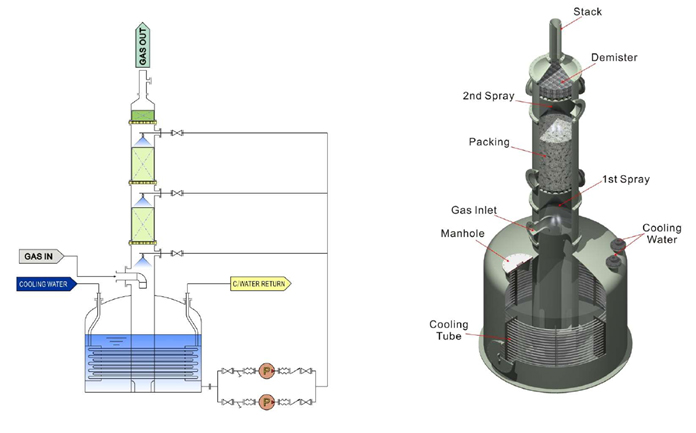

Absorption Method SCRUBBER

Absorption is the process in which a gas and a liquid contact each other in counterflow or parallel flow, allowing VOCs to transfer from the VOC-containing gas to the liquid phase

Common absorbents include water, caustic soda solutions, ammonia, or high-boiling hydrocarbons. The choice of absorbent depends on the characteristics of the VOCs; for example, if the VOCs are water-soluble, water can be an effective absorbent.

Common absorbents include water, caustic soda solutions, ammonia, or high-boiling hydrocarbons. The choice of absorbent depends on the characteristics of the VOCs; for example, if the VOCs are water-soluble, water can be an effective absorbent.

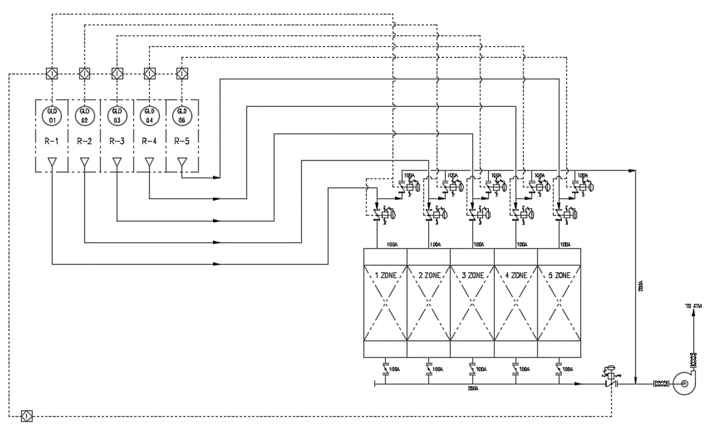

P & ID

Chemical Adsorption Tower

ADSORPTION TOWER DESIGN

흡착탑 설계기준

- 공탑 속도 : 0.35~0.5m/sec

- 체류시간 : 1 sec 이상

- Depth (흡착제 충진 두께) : 500mm

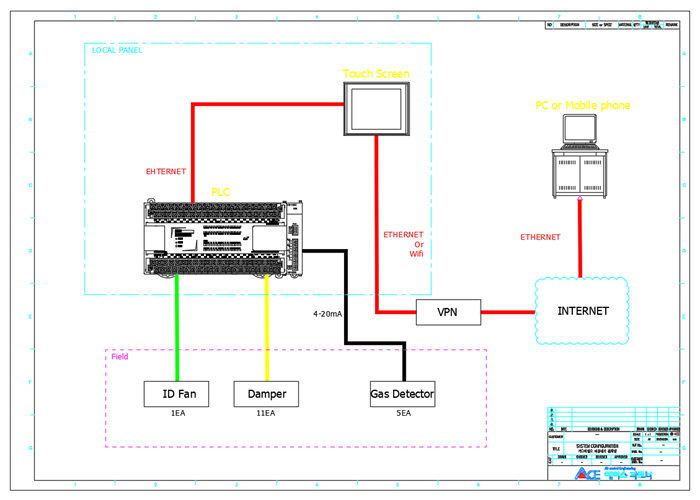

Control

Gas Chemical Adsorption Tower Operation Manual

| 상황 | 운전방법 1 | 운전방법 2 | 비고 |

|---|---|---|---|

| 평상시(GAS 유출없음) | 방지시설 및 배기팬 정지 | ROOM의 음압을 유지하기위해 배기팬만 운전 방지시설은 미운전 ( VALVE OFF) | 상황에 따라 운전방법 결정 |

| ROOM내부에 GAS 유출 발생시 | GAS DETECTOR SETTING 농도에 따라 감지 -> FAN/방지시설 운전 / ALARM 송출 -> 감지농도 이하로 떨어지면 FAN/ALARM 정지 | -> 유출된 ROOM에 설치된 GAS DETECTOR SETTING 농도에 따라 감지 -> 해당 방지시설 VALVE OPEN / ALARM 송출 -> 감지농도 이하로 떨어지면 해당방지시설 VALVE OFF & ALARM 정지 | |

| Event 발생 후 조치 | 유출 ROOM 및 방지시설 점검 -> 필요에 따라 Chemical Media 교체 진행 | 유출 ROOM 및 방지시설 점검 -> 필요에 따라 Chemical Media 교체 진행 |