Air Pollution Control Plant

Air control Engineering Co., Ltd.

Electrostatic Precipitator

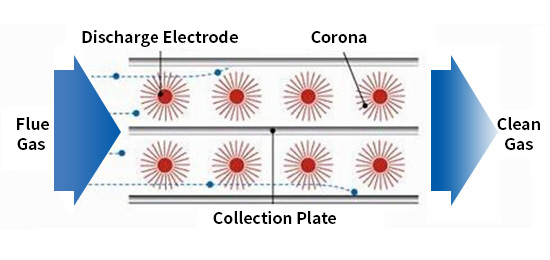

- The Electrostatic Precipitator (ESP) uses corona discharge at the discharge electrode to charge incoming gases with negative ions. Dust and particles in the gas absorb these ions, becoming negatively charged.

- These negatively charged particles are attracted to the collection electrode (positive pole, grounded) due to the electric field and Coulomb force.

Advantages

- 1Effective removal of a wide range of particle sizes

- 2High removal efficiency (including fine particles)

- 3Operates with low pressure loss

- 4Suitable for both dry and wet applications

- 5Applicable across a wide temperature range

Disadvantages

- 1High initial investment cost

- 2Difficult to control gas composition

- 3Limited responsiveness to sudden changes in inlet concentration

- 4Difficult to remove dust with very high resistivity

Electrostatic Precipitator Category

| Classification Factor | Type | Description | Etc | ||

|---|---|---|---|---|---|

| Electrode Arrangement | Single-stage Charging | Discharge and electric field formation occur in the same space; named after the inventor as the Cottrell type ESP | |||

| Two-stage Charging | Discharge and electric field formation occur in different spaces; named after the inventor as the Penney type or two-stage ESP | ||||

| Cleaning Method | Dry | Cleaning of electrodes using a mechanical cleaning method | |||

| Wet | Continuous Cleaning | Water Film | Forms a continuous water film on the collection electrode surface, preventing contamination | ||

| Mist Spray | Cleans the electrodes during operation using fine mist nozzles | ||||

| Intermittent Cleaning | Cleans electrodes with high flow intermittent spray after disconnecting high voltage | ||||

| Gas Flow | Horizontal | Gas flow occurs horizontally | |||

| Vertical | Gas flow occurs vertically, primarily from bottom to top | ||||

Types and Applications

- Electric precipitators are categorized into high-voltage single-stage charged electric precipitators and low-voltage double-stage charged electric precipitators.

Single-Stage Charging (High Voltage) 50 ~ 70 kV

- The collection section is structured with a discharge electrode that facilitates charging, resulting in excellent performance. This design is primarily used for capturing liquid and solid particles generated in various industrial processes.

- Typically used in power plants, steel mills, boiler flue gas treatment, glass melting furnaces, cement kilns, smelting furnaces, incinerators, and more.

- Wet Electrostatic Precipitator (WET ESP): Used for capturing liquid particles and acid mists in processes such as sulfuric acid manufacturing, chemical plants, and PVC production.

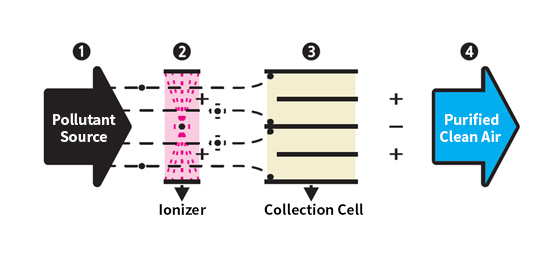

Two-Stage Charging (Low Voltage) 10 ~ 20 kV

- The structure ionizes incoming particles in a single-stage ionizer and collects them using electrostatic force in a two-stage collection cell, making it suitable for gases with low concentration.

- It is used for capturing pollutants in smoke chambers, air conditioning systems, and air purifiers.

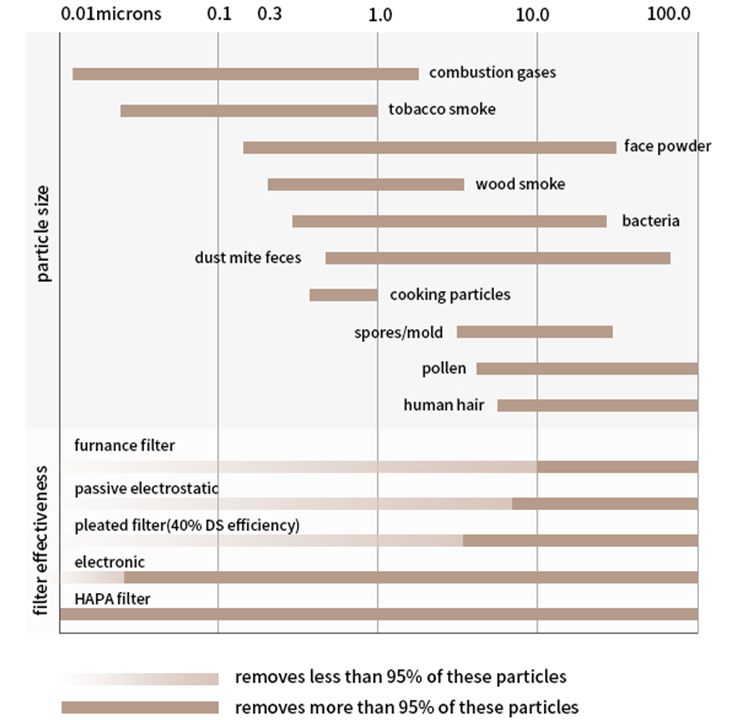

Filter/Treatment Efficiency by Particle Size

ⓒ 2006 John Wiley & Sons, Best Practices Guied to Residential Construction

Figure 1. Size range of common pollutant sources (adapted from john Wiley and Sons, Best Practices Guide to Residential Construction, 2006).

Factors Affecting Collection Efficiency During Operation

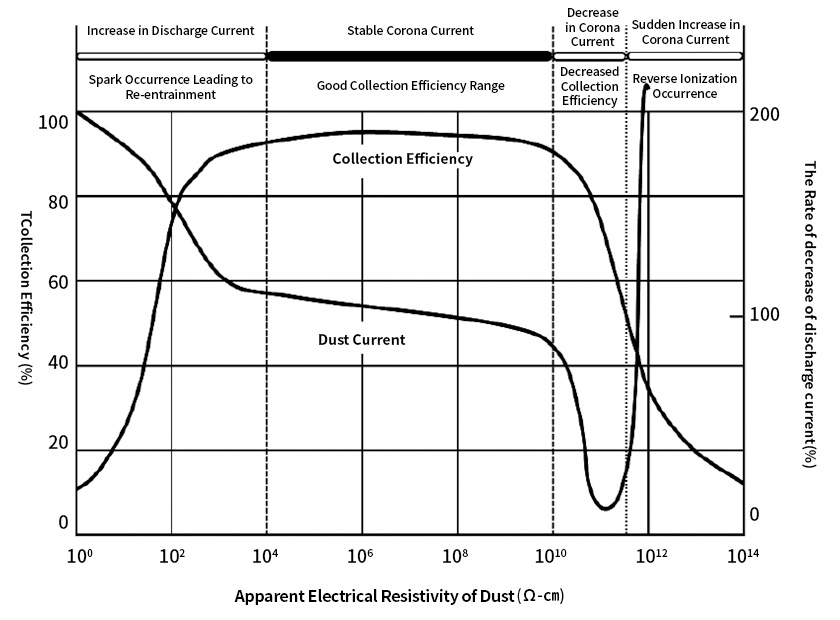

1. Electrical Resistivity of Dust

- 1Electrical Resistivity below 10^4 Ω-cm:

Dust attached to the collection plate quickly releases charge, losing adhesion and causing re-entrainment - 210^4 ~ 5 × 1010 Ω-cm: Exhibits normal collection performance

- 35 × 10^10 Ω-cm: The dust layer may cause localized thermal breakdown, leading to voltage drop. However, due to spark generation at the discharge electrode, the voltage cannot be increased, resulting in decreased collection efficiency

- 410^10 ~ 10^13 Ω-cm: The dust layer emits light, increasing discharge current and causing reverse ionization. The positive corona neutralizes the negative charge of the dust, significantly reducing collection efficiency To prevent reverse ionization phenomena, substances such as water, NHO4OH, triethylamine, SO3, various chlorides, and oils are used

2. Temperature: Collection efficiency is favorable when the temperature of the treatment gas is below 150°C or above 250℃

3. Moisture Content: As moisture content increases, electrical resistivity decreases, leading to improved collection efficiency, but caution is needed due to low-temperature corrosion.

4. Sulfur Content: Higher sulfur content in fuel decreases electrical resistivity, thereby increasing collection efficiency.

5. Gas Flow Rate and Velocity

- 1Increased gas flow rate leads to higher gas velocity, resulting in re-entrainment of particles and reduced collection efficiency.

- 2A rapid decrease in gas flow rate causes non-uniform particle distribution, leading to decreased collection efficiency.

- 3A uniform flow in a wide space must be created to enhance collection efficiency.

6. Particle Diameter: Smaller particle diameters slow down movement, reducing collection efficiency. Additionally, the larger specific surface area increases the charge and makes discharge difficult.

7. Dust Concentration: Higher dust concentration suppresses discharge current and causes voltage drop, resulting in decreased collection efficiency.

8. haracteristics of Dust

- 1Alkali Metal Components: Decrease electrical resistivity.

- 2SiO2, Al2O3, and Alkali Earth Metal Components (CaO, MgO): Increase electrical resistivity.

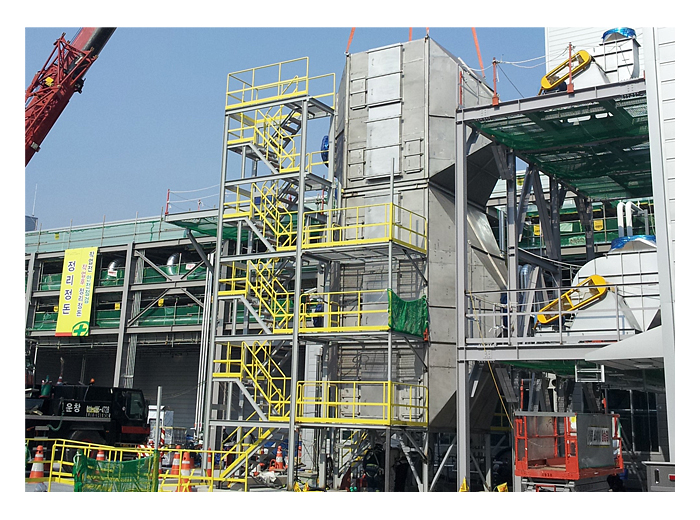

Application Case

Removal of Flue Gas and Oil Mist: SK Innovation (1700 CMM)

1단하전식 전기집진기 사진

울산 프린테크 300CMM

홍인산업 FOOSUNG 150CMM

1단하전식 습식 전기집진기 사진

2단하전식 전기집진기 사진

OO금속 150CMM

SK 이노베이션 1700CMM

SK 400CMM