ACE Environmental Technology

Air control Engineering Co., Ltd.

Fine dust and fumes generated from metalworking processes, such as welding, contain harmful substances that can lead to respiratory diseases, allergic reactions, asthma, and pneumonia. Air Control Engineering Co. Ltd. uses Computational Fluid Dynamics (CFD) simulations based on data from the source of generation to determine the appropriate hood design and required airflow. We employ filtration and dust collection technologies using nano-filters and high-efficiency electrostatic precipitators to effectively manage dust and fumes.

ACE Fume & Dust Solution & Technology

-

Double Canopy hood & Side jet air curtain

-

- Uniform Flow

- Push & Pull

- Negative pressure system

-

Double Canopy hood & Side jet air curtain

-

- High efficient HEPA & NANO filter

-

Double Canopy hood & Side jet air curtain

-

- Heat Exchange & Circulation system

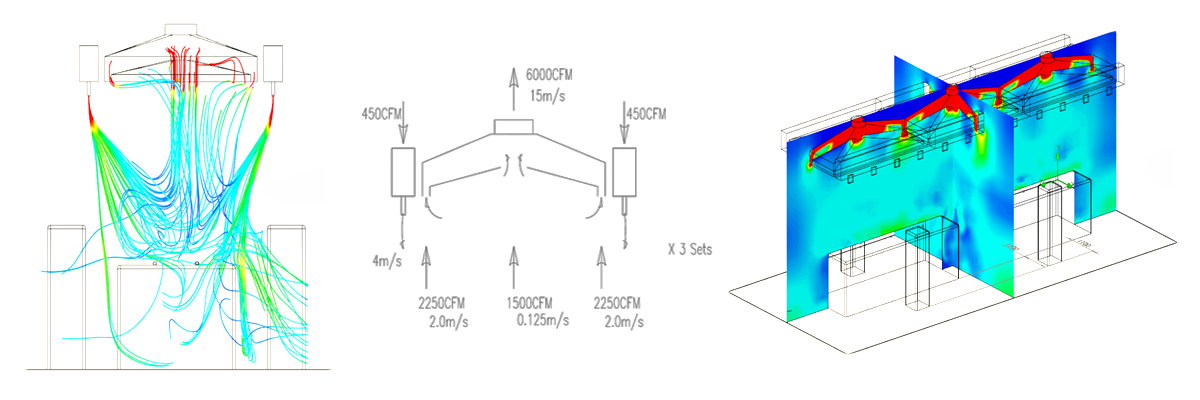

CFD (Computational Fluid Dynamics)

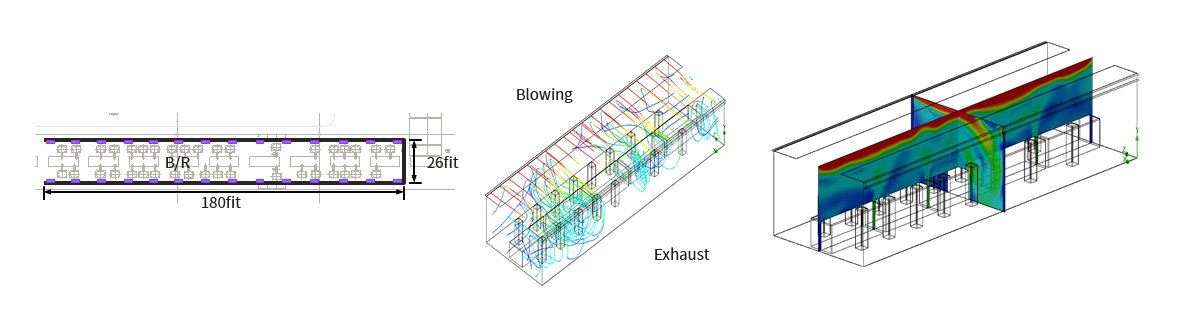

Robot welding Line

Double Canopy hood & Side jet air curtain

- Implementation of Double Canopy & Air Curtain Exhaust System for Efficient Control of Welding Fumes

- Hyundai Motor Company Robotics Welding Line, HMMA, Alabama, USA.

Push & Pull Capture system on Long distance by Entrainment effect

- Implementation of Double Canopy & Air Curtain Exhaust System for Efficient Control of Welding Fumes

TRAPPING VENTILATION

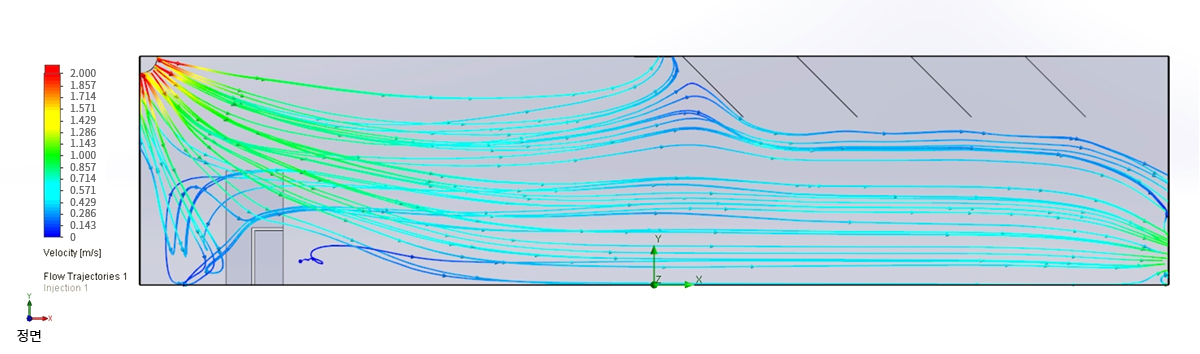

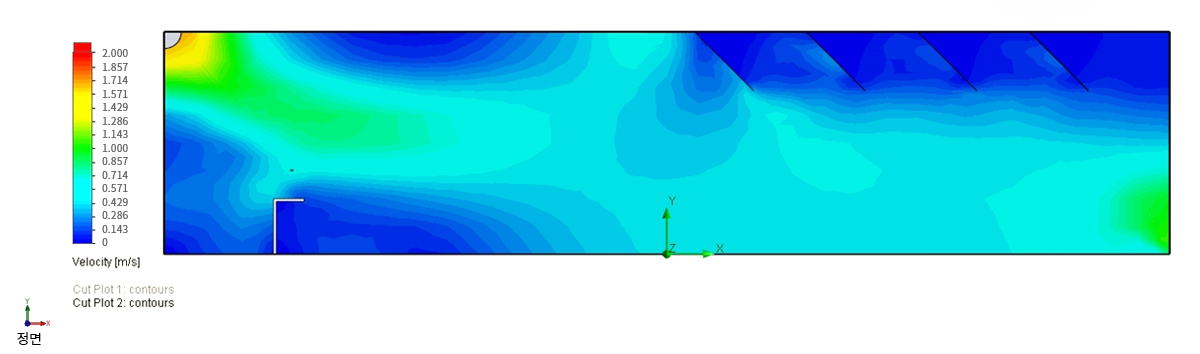

- Planning and controlling overall ventilation of the space through Flow Trajectory analysis.

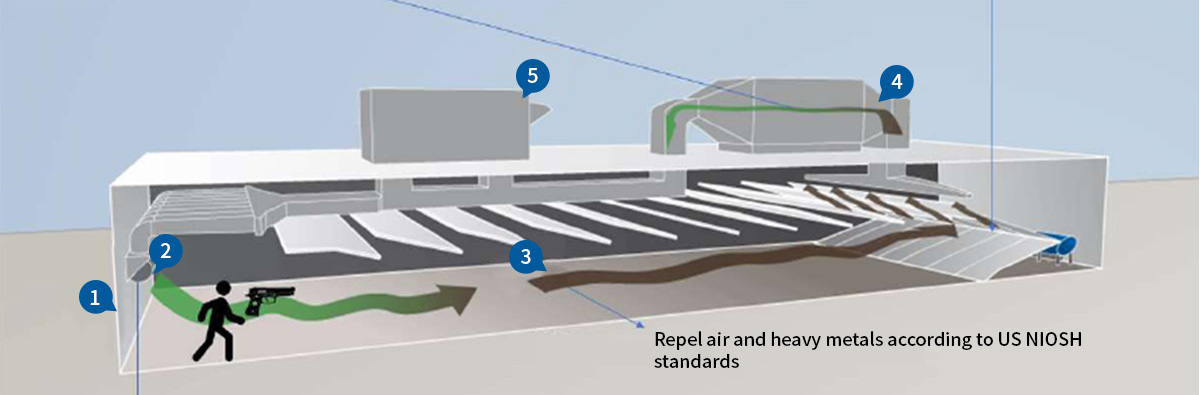

Computational Fluid Dynamics Simulation for the Indoor Shooting Range in Gyeonggi Province

Shooting range

| 1 | Shooting launcher | During shooting, (oxidized) lead heavy metal dust and gas are emitted |

|---|---|---|

| 2 | Uniform flow | Generate isothermal airflow to prevent shooters from being exposed to (oxidized) lead |

| 3 | Appropriate Velocity | Design of suitable exhaust points and airflow velocity/pressure/volume |

| 4 | Filtration Technology | HEPA/NANO FILTER |

| 5 | Energy Efficiency | Heat exchange and Circulation system |

Computational Fluid Dynamics (Side-1)

Indoor Shooting Range in Gyeonggi Province

Computational Fluid Dynamics (side-2)

Indoor Shooting Range in Gyeonggi Province

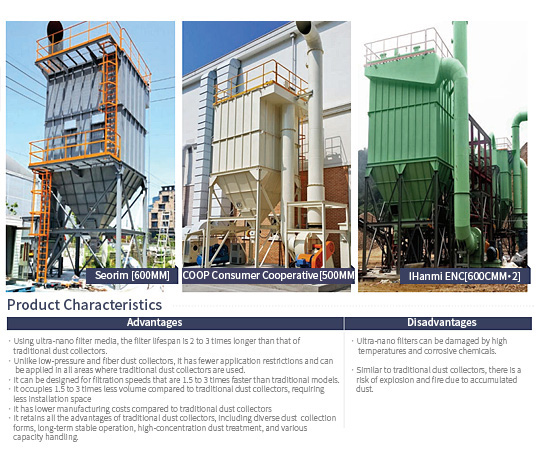

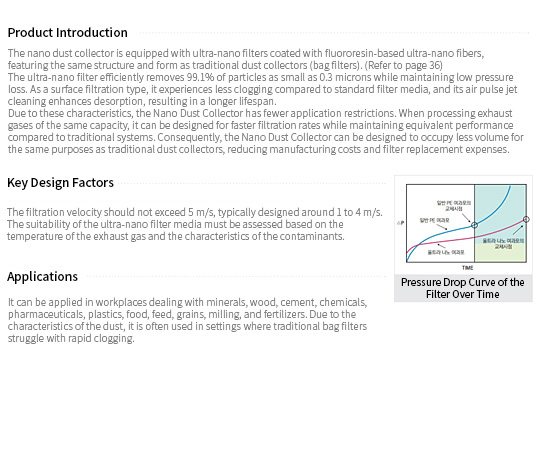

High-efficient NANO FILTER

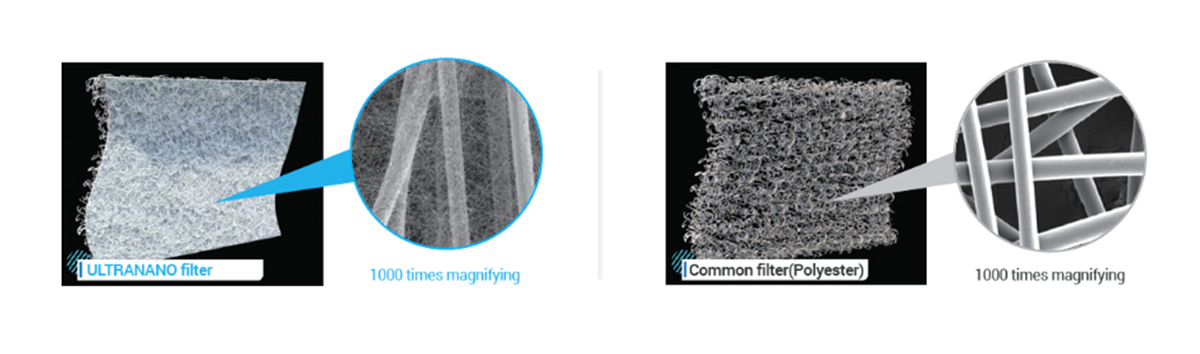

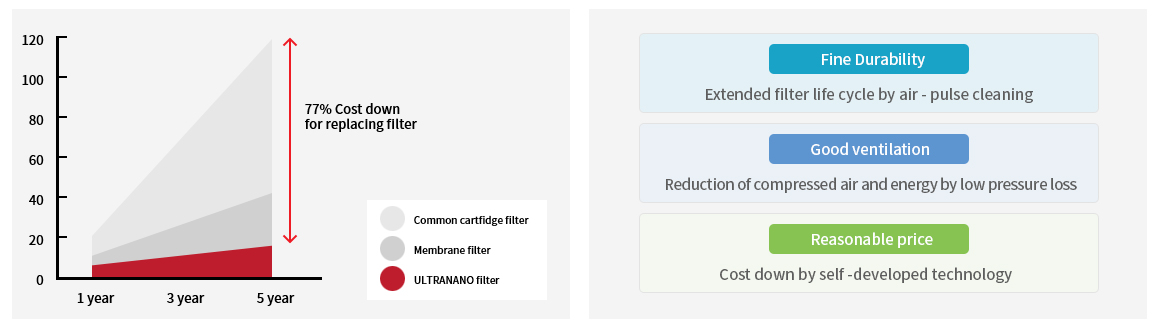

Welding fume is small and fine, so the general filter is easy to be clogged. The special filter coated with Nano fiber removes the dust 99% at 0.3 microns. In addition, the Nano Filter has superior air permeability and has superior dust removal efficiency and longer service life than general filters.

Features

- The Ultra Nano filter is coatede with one-billionth meter super fine nano fiber.

- The air hole of it is 20 times smaller and closer than common polyester fiter.

- By Surface filtration, the dusts are not stuck in the hole of fiber unlike depth filtration.

- The dusts are easy to be off when air-pulsing, so the life cycle is longer then common filter.

The efficiency of Ultra Nano : Effciency of filtration

| Type | PE filter(KOLON L227) | Imported NANO filter | Ultra Nano filter |

|---|---|---|---|

| Particle size | 0.3~0.5㎛ | 0.3~1㎛ | 0.3~0.5㎛ |

| Filtering rate | 86.2% | 85~95% | 99.1% |

Effectiveness

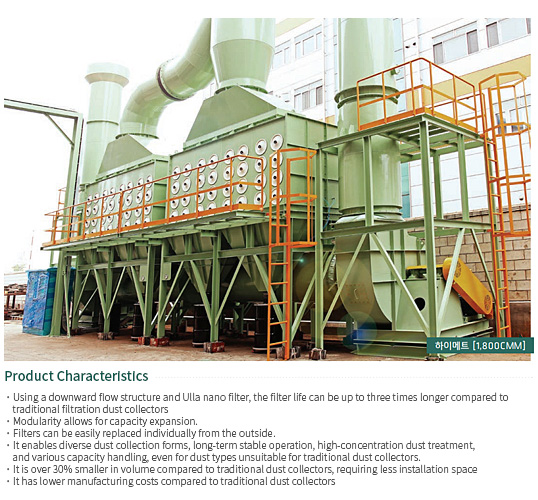

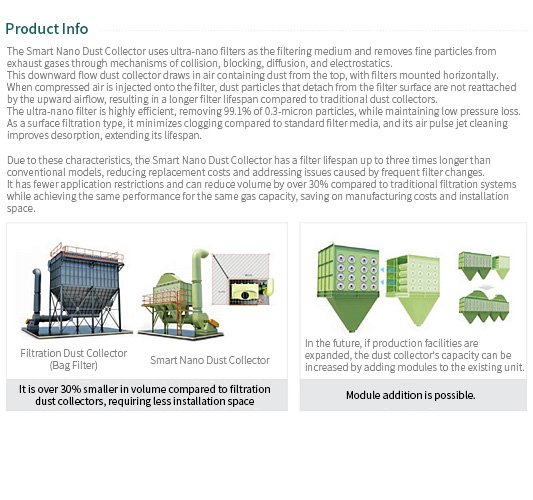

Applied Dust Collection Facility

- Smart Nano Dust Collector Model SND

- Nano Bag Filter Dust Collector Model CDN